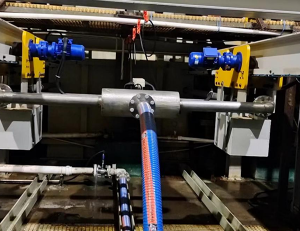

Wire rod pickling&phosphating line

Izinzuzo kanye nokuthuthukiswa komkhuba wokwelashwa kokukhetha okuzenzakalelayo:

Imishini yokwelapha yokukhetha indawo ezenzakalelayo inezinzuzo ezingenakuqhathaniswa nezindlela zendabuko zokukhetha nezinye izindlela zokwelapha ezingena-asidi:

★Izinga eliphezulu eliphezulu—— into esetshenziswayo iseyi-asidi, ngakho-ke ikhwalithi ephezulu isagcina izinzuzo zokukhetha okungokwesiko;

★Ukukhiqiza okuzenzakalelayo-- ukukhiqizwa okuzenzakalelayo okuqhubekayo, ukusebenza kahle kokukhiqiza okuphezulu, okukhiphayo okukhulu, imingcele yenqubo ehlukahlukene ilawulwa yikhompyutha, ukukhiqizwa kuye kwaba ngokuzenzakalelayo.Inqubo izinzile, ifaneleka ikakhulukazi ukukhiqizwa kwevolumu enkulu, endaweni eyodwa;

★Izindleko zokukhiqiza eziphansi—— Ukulawulwa okuzenzakalelayo kwemingcele yenqubo, inqubo yokukhiqiza ingenziwa elungiselelwe, ngokusakazwa kwemidiya yokukhiqiza okunengqondo nokusebenzayo.Ukusetshenziswa kwendandatho, kuyilapho ukukhiqiza okuzenzakalelayo kunganciphisa ngempumelelo izindleko zabasebenzi.Lezi zici zenza imishini yokukhetha ezenzakalelayo.Izindleko zokusebenza zemishini ziphansi kakhulu kunezokuqoqwa kwendabuko;

★Ukungcoliswa kwemvelo okuphansi—— umshini wokucosha ozenzakalelayo ungahlonyiswa ngamanzi alahlwayo athuthukile kanye nemishini yokuhlanza igesi engcolile, kuhlanganiswe nezici zemishini yayo, Ukuzuza ukukhishwa kwekhabhoni ephansi uma kuqhathaniswa nokungcoliswa okuncane embonini nasezindaweni ezizungezile.Ikakhulukazi ekwelapheni inkungu ene-asidi nokwelashwa kwamanzi.Ngakolunye uhlangothi, uma ifakwe imishini efanelekile yokukhiqiza kabusha i-asidi kanye nemishini yokuhlanza amanzi angcolile, ukukhishwa kwe-zero kungafinyelelwa.

★ Ngokuthuthuka kobuchwepheshe, imishini yokukhetha ezenzakalelayo izoqaphela kancane kancane ukuxhumeka okungenamthungo ngokulandelelwa kwezinto, i-MES, i-ERP nezinye izinhlelo.Ngomkhakha 4.0, umbono womshini, idatha enkulu yamafu nobunye ubuchwepheshe, kungafinyelela izinga eliphezulu lokukhiqiza okujulile, okuzenzakalelayo, kanye nezinhlobonhlobo eziningi, okuletha izinzuzo ezinkulu zezomnotho ebhizinisini.

Ukukhethwa kwezisetshenziswa

Umehluko phakathi kwezinhlobo ezahlukene zemigqa yokukhetha:

★uhlobo lwendilinga—— olufanele izinto zenduku ye-carbon wire rod ephezulu nephansi enezidingo zenqubo efanayo, esebenza kahle kakhulu, ephumayo enkulu kanye nokubekezelela okuhle kwamaphutha;

★Uhlobo lwe-U—— lufanelekela izinduku zezintambo zekhabhoni eziphakeme neziphansi nezinsimbi zensimbi engagqwali ezinezinhlobonhlobo nezidingo zokucubungula, eziphumayo ezinkulu;

★uhlobo oluqondile—— olufanele abakhiqizi abanesakhiwo sesitshalo esihlangene kanye nezidingo eziphansi zokukhishwa.Awukho umkhawulo ezinhlobonhlobo zezintambo zocingo.

Ukucushwa kwenqubo okujwayelekile

Izici

★ Isizukulwane esisha sama-manipulators:

• I-hoist kagesi eyenziwe ngokwezifiso ngokukhethekile yolayini wokukhetha, enezinga eliphezulu lokuvikela kanye nokumelana nokugqwala;

• Ukulawulwa kokushayela ngamasondo amane, ama-motor angu-4 ahambayo asebenza ngokuhambisanayo, okuthuthukisa kakhulu ukwethembeka nokubekezelelana kwamaphutha ekusebenzeni kwemishini;

Ukuhluleka kwe-motor eyodwa akuthinti ukusebenza kwe-manipulator;

• Uhlaka lwe-pulley olunyakazayo olunomhlahlandlela wamazwe amabili oluhlanganiswe nesakhiwo esiqondisayo sengalo yerobhothi siqinisekisa ukusebenza okuzinzile nomsindo ophansi;

• Uhlaka lwe-pulley olugudlukayo lusebenzisa indlela yesondo eliqondisa izindlela ezintathu elinesakhiwo esingu-2×2 ukuze kuqinisekiswe ukuthi inqubo yokuphakamisa nokwehlisa izinzile futhi ayinyakaziswa;

• Indlela yokuqondisa yamaqembu amaningi enesakhiwo esingu-2×4, isiteringi esivumelana nezimo, umsindo ohamba kancane, futhi akukho ukuminyana kukaloliwe;

• I-radius ephendukayo yethrekhi ingaba encane njengamamitha angu-3, futhi isakhiwo sihlangene.Uma kuqhathaniswa nemikhiqizo efanayo, igcina i-1/3 yendawo yefekthri;

• I-manipulator ayixhumani ngokuqondile nethrekhi ngesikhathi sokuhamba, futhi ithrekhi ayigqoki;

• Ifakwe isifaki khodi sokuphakamisa inani eliphelele ukuze kulawulwe ngokunembile indawo yokuphakamisa nokuqapha isimo sokuphakamisa ngaso sonke isikhathi ukuze kuqinisekiswe ukusebenza okuphephile;

• I-manipulator ngayinye ifakwe inzwa yokumisa eqondile, ehlala ibuyisela isimo samanje sokusebenza kwe-manipulator, ngokulungiswa okungu-0.8mm, iqinisekisa ukuthi i-manipulator isebenza ngokunembile;

• Isakhiwo semishini esilungiselelwe ngokukhethekile, impilo ende yesevisi yezingxenye, ukugcinwa nokulungisa kalula, kanye nokushintshwa ngokushesha kwezingxenye.

• I-hoist kagesi eyenziwe ngokwezifiso ngokukhethekile yolayini wokukhetha, enezinga eliphezulu lokuvikela kanye nokumelana nokugqwala;

• Ukulawulwa kokushayela ngamasondo amane, ama-motor angu-4 ahambayo asebenza ngokuhambisanayo, okuthuthukisa kakhulu ukwethembeka nokubekezelelana kwamaphutha ekusebenzeni kwemishini;

★ Ukwehluleka kwemoto eyodwa akuthinti ukusebenza kwe-manipulator;

• Uhlaka lwe-pulley olunyakazayo olunomhlahlandlela wamazwe amabili oluhlanganiswe nesakhiwo esiqondisayo sengalo yerobhothi siqinisekisa ukusebenza okuzinzile nomsindo ophansi;

• Uhlaka lwe-pulley olugudlukayo lusebenzisa indlela yesondo eliqondisa izindlela ezintathu elinesakhiwo esingu-2×2 ukuze kuqinisekiswe ukuthi inqubo yokuphakamisa nokwehlisa izinzile futhi ayinyakaziswa;

• Indlela yokuqondisa yamaqembu amaningi enesakhiwo esingu-2×4, isiteringi esivumelana nezimo, umsindo ohamba kancane, futhi akukho ukuminyana kukaloliwe;

• I-radius ephendukayo yethrekhi ingaba encane njengamamitha angu-3, futhi isakhiwo sihlangene.Uma kuqhathaniswa nemikhiqizo efanayo, igcina i-1/3 yendawo yefekthri;

• I-manipulator ayixhumani ngokuqondile nethrekhi ngesikhathi sokuhamba, futhi ithrekhi ayigqoki;

• Ifakwe isifaki khodi sokuphakamisa inani eliphelele ukuze kulawulwe ngokunembile indawo yokuphakamisa nokuqapha isimo sokuphakamisa ngaso sonke isikhathi ukuze kuqinisekiswe ukusebenza okuphephile;

• I-manipulator ngayinye ifakwe inzwa yokumisa eqondile, ehlala ibuyisela isimo samanje sokusebenza kwe-manipulator, ngokulungiswa okungu-0.8mm, iqinisekisa ukuthi i-manipulator isebenza ngokunembile;

• Isakhiwo semishini esilungiselelwe ngokukhethekile, impilo ende yesevisi yezingxenye, ukugcinwa nokulungisa kalula, kanye nokushintshwa ngokushesha kwezingxenye.

★ Isakhiwo esiqinile, isakhiwo sensimbi esenziwe efekthri, uxhumano lwebhawodi olunamandla amakhulu, ukwelashwa okubanzi kokuqeda ukugqwala

• Kulula ukunakekela nokonga ekutshalweni kwefekthri;

• Isiteshi sokunakekela sifakwa ngaphakathi komugqa wokukhiqiza futhi asihlali endaweni yangaphandle;

• Inamandla futhi iphephile kune-welding yendabuko, iqede ngokuphelele ukucindezeleka;

• Izinto zokusebenza zinhle futhi zinhle, kulula ukuzifaka, futhi isikhathi sokwakha sifushane;

• Ingaphezulu lesakhiwo sensimbi esiyinhloko liyadutshulwa liqhunyiswe ukuze kuqinisekiswe ukuthi i-anti-corrosion coating elandelayo iqinile futhi iqinile;

• Ngemuva kokudubula, indawo engaphezulu iphathwa nge-anti-corrosion coating, futhi ifuthwe ngenjoloba ene-chlorine evimbela ukugqwala, ngakho-ke kungabikho ukukhathazeka ngokugqwala.

★ I-Pickling isebenzisa ubuchwepheshe bokuhlunga be-tank yangaphandle:

• ubuchwepheshe obunelungelo lobunikazi;

• Azikho izinto zokushisisa namakhoyili ethangini lokukha;

• Ukukhethwa okunamandla kwezintambo zocingo kuthuthukisa umphumela wokukhetha, futhi izikhala zezintambo zocingo nazo zingavuthwa kahle;

• Thuthukisa ukusebenza kahle kokukhetha ngo-10–15%;

• Izinsalela zokuhlunga eziku-inthanethi ngaphandle kwethangi, ukususwa kwezinsalela ku-inthanethi, kwandise impilo yesevisi ye-hydrochloric acid ngaphezu kuka-15%, futhi konga izindleko zokukhiqiza;

• Umjikelezo wokuhlanza nokunakekela ithangi le-asidi mude, wehlisa izinga lomsebenzi.

★ Ubuchwepheshe obusebenzayo bokugaywa kabusha kwamanzi:

• Ukuhlanzwa komjikelezo wamanzi okuhambisana ne-synchronous kuqinisekisa ukusetshenziswa kancane kancane kwemithombo yamanzi;

• I-steam condensate igaywa kabusha ethangini lamanzi afudumele;

• Ukusetshenziswa kwamanzi kungaba ngaphansi kuka-40Kg/ton, kunciphisa izindleko zokukhiqiza.

★ Uhlelo olugcwele lwe-Flush:

• Ukugungiswa kokucindezela okuphezulu ngesikhathi esisodwa kwendawo yangaphakathi nangaphandle yentambo yocingo;• Ukusebenzisana nomshini wokuzungezisa wentambo, ingageza indawo yokuthintana yenduku yocingo kanye nehuku ngaphandle kwamaphethelo afile;

• I-nozzle ngayinye eshaywayo ifakwe ijoyinti elilodwa le-universal, elingalungiswa libe i-engeli engcono kakhulu yokushaywa;

• Umshini wokuwasha uyavumelana nezimo futhi unhle kakhulu, futhi ukunakekela kulula futhi kulula;

• Ukulawula iphampu yamanzi kabili, iphampu yamanzi enengcindezi ephezulu inesibopho sokushaywa, futhi iphampu yamanzi enengcindezi ephansi ifutha ingaphezulu lenduku yocingo ukuze ivikeleke;

• Amanzi okugeza asetshenziswa ngokuphindaphindiwe ngaphandle kokukhathazeka ngokusetshenziswa kwamanzi.

Qaphela: Inqubo yokuhlanza ngemva kokukhetha ibaluleke kakhulu kuyo yonke inqubo yokuqoqa kanye ne-phosphating, ethinta ngokuqondile ukwelashwa okulandelayo kwe-phosphating;umphumela omubi wokuhlanza uzofinyeza impilo yesevisi yesisombululo se-phosphating.Ngemuva kokuthi i-asidi esele ilethwe kwisisombululo se-phosphating, isisombululo se-phosphating kulula ukuphenduka sibe mnyama, futhi impilo yesevisi ifinyelelwe kakhulu;ukuhlanza okungaphelele kuzophinde kubangele ikhwalithi ephansi ye-phosphating, indawo ebomvu noma ephuzi, isikhathi sokugcina esifushane, kanye nokusebenza kabi komdwebo.Abakhiqizi bemikhiqizo yensimbi abanezidingo eziphakeme basebenzisa isistimu yokuguquguquka ebanzi.

★ Isistimu ye-phosphating ethuthukisiwe futhi ehlala njalo kanye ne-slag

• Ukusebenza okuzenzakalelayo ngokugcwele ngaphandle kokusebenza ngesandla;

• Isistimu yokuhlunga indawo enkulu, ukuhlanza okuzenzakalelayo kwe-slag nokukhishwa kwe-slag;

• Uketshezi olucacile lwe-phosphating lubuyiselwa ngokuzenzekelayo ethangini le-phosphating, akukho ithangi le-phosphating elihlanzekile elingeziwe elidingekayo;

• Ukulahlekelwa ukushisa kwesisombululo se-phosphating kuncane ekusetshenzisweni kokuhlunga okujikelezayo, okusiza ukunciphisa ukusetshenziswa kwamandla;

• Ukusebenza okuthembekile, indawo encane, umsindo ophansi kanye nokusetshenziswa kancane kwamandla;

• Ukusebenza okulula, izindleko eziphansi zokusebenza kanye nokugcinwa okulula.

★ Uhlelo lokulawula oluthuthukisiwe kanye nomklamo wohlelo othembekile:

• Ukuma kwezindlela ezimbili kwenzwa yomugqa kanye neswishi ye-proximity, kuhlanganiswe ne-algorithm yesofthiwe, ukuvimbela izingozi zokushayisana;

• Ukulawulwa okuqinile kokuphepha kanye nokumiswa kwezinzwa zokuphepha ukuze kugwenywe izingozi zomuntu siqu nokuqinisekisa ukuphepha kwabasebenzi;

• Ukunemba kokuma okuphezulu, iphutha lokubeka ≤ 5mm;

• Isikrini sokubonisa ku-HMI sihambisana ngokuphelele nendawo yamanje ye-manipulator ekusayithi kanye nendawo yokuphakamisa ihuku;

• Abasebenzisi bangakwazi ukwenza ngokwezifiso izinqubo ezihlukahlukene zenqubo;

• Ngokohlobo lwenduku yocingo, u-opharetha angakhetha inqubo yokukhetha kanye ne-phosphating ngokhiye owodwa lapho elayisha;

• Inqubo yokukhiqiza ingalungiswa nganoma yisiphi isikhathi phakathi nenqubo yokukhiqiza, ngokulawula okuvumelana nezimo;

• Landelela futhi urekhode isimo senqubo yekhoyili ngayinye ngesikhathi sokukhetha kanye nenqubo ye-phosphating;

• Umsebenzi we-BYPASS, ongaqaphela ukuhlanza kabusha ukhiye owodwa;

• Imibiko ehlukahlukene ingenziwa ngokwezifiso ngokwezidingo zabasebenzisi, okulula ukuthi abasebenzisi bayibuze futhi bayirekhode;

• Sebenzisa isango le-Ethernet yezimboni ezingenazintambo ukuze ufanise isango le-PLC ukuze uthole ukulawula okuthembekile nesikhathi sangempela;

• Ingakhetha ukusebenzisa i-RFID noma isistimu yebhakhodi, ifanise inqubo ngokuzenzakalelayo, futhi ilandelele indlela yenduku yocingo nganoma yisiphi isikhathi;

• Ungakhetha ukusebenzisa i-inthanethi Yezinto, isilawuli seplathifomu yamafu, nomakhalekhukhwini namathebulethi kungaba ku-inthanethi ukude;

• I-interface yesistimu ye-MES ingagodlwa, futhi isistimu ye-MES ingaxhunywa ngaphandle komthungo nale mishini, elungele ukuphathwa kokukhiqiza.

★ Ukuphathwa kwekhwalithi eqinile nokukhiqiza:

• Zonke izakhiwo zensimbi nama-manipulators angaphansi kokutholwa kwamaphutha;

• Wonke amathangi ahlolelwa amahora angama-24-48 wokugcwaliswa kwamanzi;

• Wonke amakhabethe okulawula ugesi kanye namakhabethe okusabalalisa amandla ahambisana nesitifiketi se-3C.